Since optimization starts with the component, Bürkert has developed Element – a new series that allows breweries and beverage manufacturers to significantly improve product safety and the reproducibility of their processes. In addition to good cleaning properties and hygienic design, the concept offers a complete modular system, including process valves and controls, for automation in hygienic environments. Process valves are often installed with two in-pipe flange connections to facilitate replacement. Conversely, Element process valves are usually permanently welded into the pipe.

This eliminates the need for sealing points and two additional welding seams as well as making installation easier and more economical, although it also makes it harder to remove the valve. Taking this into account, the Element stainless steel body includes a valve seat thread accommodating screw-in seats of varying orifices. When combined with matching replaceable control cones, flow properties can be tailored to the process, effortlessly optimised at a later time or adapted to new process conditions. Installing Bürkert control valves in media lines, for example, paves the way to transform energy consumption by changing the valve seat. Even greater energy savings are possible if the valves are equipped with a sealing function.

Element controls for decentralized automation directly on the valve feature a completely modular design and can be assembled to meet the precise functional requirements of the user. Control heads provide valve feedback, pilot valves or both combined. Position controllers perform control functions. Conversely, the process controller type 8693 for stroke movements can also be used to control temperature, flow rate and pressure without a higher-level controller. This means, for example, that controlling wort cooling or cooling water in a refrigeration system is feasible.

With Sidecontrol position and process controllers, Bürkert engineers have already modernised the air flap control of a malting plant. The device functions as a position and process controller for rotation movements. It can also be used to control valves and damper positions on other products and does not need to be attached directly to the valve. This opens up a wealth of potential for cost-effectively modernising systems when the time comes to replace older position controllers with permanent compressed air consumption. The use of standardised interfaces allows products from many manufacturers to be replaced without difficulty.

Moreover, the contactless approach of Element positioners and control heads renders them impervious to pressure surges – improving the process reliability and reproducibility of all switching processes and extending the service life of the equipment involved. Element control heads are supplied with clean pilot air, which is fed into the spring chamber and control head after switching. The resulting overpressure prevents the ingress of moisture, cleaning agents and impurities into the interior. Yet another example of the pinpoint attention to detail to ensure unmatched hygiene.

Intelligent pneumatics and process reliability

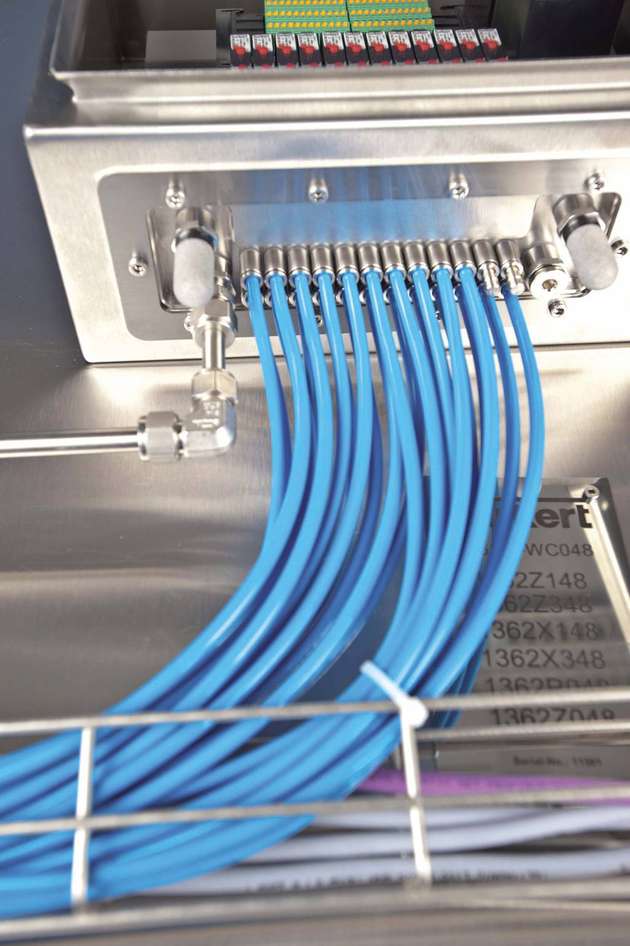

Compressed air is another area in which Bürkert takes a holistic approach: The automation system type 8614 installed in the IP65-compliant local control box combines the advantages of centralised and decentralised automation. Valve islands used in the switch box are compact and can pneumatically control all process valves as well as system feedback. Pilot valves are simple to replace – even while a facility is running thanks to the optional P blocking function.

Process safety functions such as non-return valves in the venting channel (R+S) prevent brief and unintentional ventilation of adjacent valves. This also eliminates the possibility of undefined switching states or undefined media compounds. The design, featuring a range of pneumatic modules, means up to 24 3/2-way valve functions can be implemented on a single valve island. Electrical connection technology, meanwhile, may include fieldbus interfaces, group connection or multipole interfaces. With the help of the stainless steel Airline Quick adapter

plate, the valve island is simply mounted on the base or wall of the control cabinet.

The Airline Quick valve island is installed in a Rittal Hygienic Design compact control cabinet and comes fully pre-wired. The installation can then be located adjacent to the valves in a hygiene-sensitive process environment, cutting material and installation costs and making cleaning easier.

.jpg)