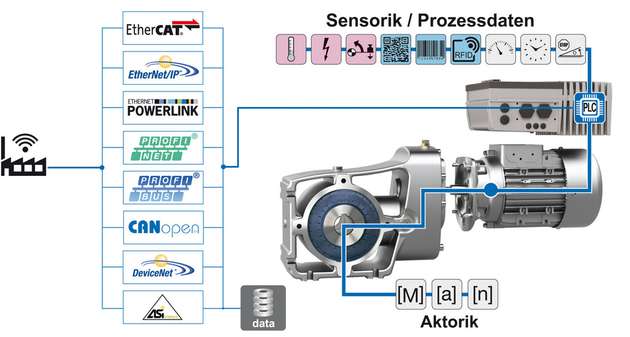

Transport and distribution of drinking water, conveying of waste water, circulation of activated sludge or comparable process engineering applications: Pump systems, as well as mixers and agitators, are elemental components in process and waste water engineering systems, and ensure the smooth operation of sewage treatment plants, waterworks, production plants, cooling systems or conveyor lines. They often have to circulate large volumes of liquid or highly viscous substances. Therefore, availability, reliability and a long service life are the top priorities. As a system supplier, Nord offers fully matched drive systems consisting of gear unit, motor and frequency inverter that are tailored to the respective requirements of the customer application. Nord drive solutions can be networked, operate autonomously, and their functions and performance are scalable. In the course of the advancing digitalisation of industrial production, the pump industry is also moving away from central control towards decentralised intelligence that controls processes autonomously, identifies faults and independently solves problems. The decentralised drive systems form master-slave groups that intelligently communicate with each other, and autonomously monitor and control the entire pump system.

PLC independently performs control functions

The frequency inverter is the brain of the drive. In decentralised concepts, it is directly mounted on the geared motor. As standard, it is equipped with a PLC that can autonomously perform control functions and reduce the load on the higher level control system. Thus, among other things, the frequency inverter can adjust pressure and flow rates of the pumped liquids in line with the actual requirements. In this way, no excess energy is wasted on valves and flaps. The frequency inverter perfectly adjusts the performance to the actual demand, regardless of whether a fixed setpoint has been set, or whether it is manually adjustable.

The integration of the PLC into the frequency inverter enables the Nord drives to record the drive and pump data (for example flow rate, pressure, pressure difference and temperature), to evaluate all of the available sensor and actuator data, to provide optimised diagnostic facilities and to communicate the data to the higher level control system or a cloud solution via the bus system. Continuous monitoring of the field level and linkage of communication, sensors (temperature, current consumption), process data (torque, acceleration, speed) and vital parameters of the drive allow for the implementation of a condition monitoring using Nord drive systems. This is the basis for a status-oriented maintenance with the aim of reducing unscheduled downtimes, lowering service and maintenance costs, and increasing the service life of the drives and connected pumps.

Advantages for agitators through optimal equipment

Especially for agitators and based on its comprehensive modular geared motor system, NORD delivers complete drive solutions covering wide speed ranges with great cost-efficiency from one source. Thanks to the easy to clean and corrosion-resistant aluminium housing, they achieve a better heat dissipation than drives with other housing materials. High process-related radial and axial loads occur in pump, mixer and agitator applications. The Nord Drivesystems range includes optional versions so that the drive can optimally absorb the occurring forces. They comprise an agitator version (VL2 bearing) with increased bearing spacing and reinforced output shaft bearing, as well as a Drywell version (VL3 bearing) with additional oil drip plate and leakage or oil sensor. For the VL2 and VL3 bearings, the bearing spacing is increased with attached components whereas the gear unit size remains unchanged. This enables maximum radial and axial load capacities and a higher service life of the gear units. NORD also offers bearings that were intentionally oversized to meet the requirements of applications such as pumps or agitators.

Less efforts, greater operational reliability

For agitator applications, the industrial gear units can also be equipped with a Safomi-IEC adapter. Safomi is available for parallel gear units and in the sizes 7 to 11, i.e. for maximum output torques from 25 to 75 kNm. Safomi is the abbreviation for Sealless Adapter For Mixers. The compact combination of Maxxdrive industrial gear units, Safomi-IEC adapter and drive motor is the best choice for mixer and agitator applications to reduce wearing parts and attached components. The Safomi-IEC adapter has a compact and simple design, and is equipped with an integrated oil expansion volume. Oil tanks and hoses as well as the radial shaft seal that is subject to leakage and wear between gear unit and IEC cylinder are not required. As standard, the combination of a parallel gear unit and Safomi-IEC adapter is only installed in installation position M5, i.e. with an output shaft pointing downwards. The change to a Safomi-IEC adapter instead of the standard IEC adapter on the agitator drive increases operational reliability and lowers maintenance costs. The oil level as well as the required oil volume is lower and thanks to fewer attached components, the installation space is also reduced.

Chemical, pharmaceutical, food or waste water industry – the robust drive solutions from Nord Drivesystems offer top reliability and ensure smooth operation. Reinforced and larger output shaft bearings allow the gear unit to absorb the high axial and radial forces and thus prolong the service life. In combination with the decentralised frequency inverters and their options of intelligent control, networking and diagnosis, drive solutions from Nord Drivesystems are Industry-4.0-ready and suitable for all future requirements of process and waste water engineering systems.