One of the main requirements for Hecht projects was to produce large quantities and convey them as gently and safely as possible to the next process step. This, at a glance, harmless task has resulted in a new development for pneumatic conveying. The client is one of the leading manufactureres for food supplements and nutraceuticals in the private and sports areas. Various solid ingredients of soluble and insoluble powders and bulks had to be conveyed. This time the flow rate also had to be considered, which normally is not so important in the process.The parameters in vacuum conveying which are already well known are the specific particle size distribution or the hygroscope.

Pressure or vacuum?

Mechanical conveying systems such as screw conveyors, could handle these quantities (8t/h, 24 hours a day in three shifts), but the required space for these systems is enormous. Additionally the required gentle transport of bulk material quickly shows the limitations of mechanical conveying. By contrast, pneumatic conveying is a particularly gentle method, but handling the amounts is difficult. Depending on the application, you can use pressure or vacuum systems. However, pressure vessels are required for pressure conveying. Because of this fact, pressure vessel acceptance inspections like the ASME certification are required.

The flow rate is strongly linked to the relevant filter characteristics of the vacuum conveyor. The better the filter can be cleaned and the larger the filter surface, the greater the flow rate. However, even proven filter concepts have not provided the necessary results here. Because of the high complexity of these requirements and the facilities as well as their significant influence on the final product, a system had to be found that would enable safe, continuous and efficient production. The critical points of this project can be summed up as follows:

Powder or bulk solid products have to be transported reliably and gently.

The system is supposed to be self-contained, so that the operator and product protection is guaranteed at all times.

Large amounts must be transported continuously or discontinuously.

For products with a low minimum ignition, it may be necessary to produce in the absence of oxygen.

No product segregation is allowed.

Cleaning should be straightforward and meet hygienic and regulatory guidelines.

All these requirements can be dealt by Hecht technology due to its many years of experience in pneumatic conveying. The ProClean Conveyor 700, which was especially developed for these tasks, meets the stringent GMP and FDA requirements of the customer. Firstly the operating principle of the ProClean Conveyor 700 cannot be distinguished from conventional pneumatic conveying: a vacuum pump is connected via pipe or hose to a charging station, for example a Big Bag discharge station. The vacuum produced by the pump (<100 mbar absolute while dense phase conveying) conveys the bulk material. By adding conveying air, the flow rate of the conveyed material can be influenced; different modes are selectable depending on the setting, for example dilute-phase conveying, plug conveying and dense-phase conveying. Especially plug conveying can avoid particle segregation.

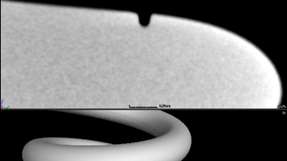

The particle-gas mixture enters the separator vessel via a product inlet valve. In contrast to the described process, the innovative aspect of the new conveyor unit is the fact that the mixture is separated from the filter unit. Several filters separate the powder from the conveying air. The filters are cleaned with compressed air in sequence. As a result of this advantage, the cycle does not have to be interrupted, so an almost continuous conveying process is possible. By changing the gas flow direction, the particles are separated from the filter. Due to gravity, the product is deposited in the separating vessel, or in case of a flange version into the corresponding vessel. There are no further connections at the filter head, which is unique. Instead, the connections are mounted laterally at the separator vessel. As a result of this, the filters can be changed easily and with enormous time savings. Depending on product, flow rates up to 10,000 kg / h are possible. These quantities are completely new in the field of pneumatic conveying. There are appropriate solutions for the requirements of different industrial sectors and environments. A horizontal filter installation is possible for buildings with low ceilings. Integration into existing systems by using a flange station is also conceivable.

Full view inside

Installing a sight glass in the cover is a great option. This makes it possible to observe the conveying process in detail at any time. So a manual fine adjustment of the conveying process and the conveying cycles is always possible. You can also be sure that it is clean inside during the cleaning process without having to open the housing. Of course the PCC meets all requirements of cleaning validation. In the case of appropriate validation, the PCC can be fitted additionally with a WIP (Washing In Place) unit.

For the project, six super-sack discharge stations were installed, which supply the pneumatic conveyors. The transported bulk material is stored temporally in buffer tanks with a volume of 2000 dm3 each, before it is discharged by gravity into a mixer for further processing. Because of the additional buffer space, the conveyor and the mixer can be operated independent of each other. After mixing, the bulk material is conveyed pneumatically to the so-called High Speed Filling Lines by using several dozen standard ProClean Conveyors with ring filter technology. The advantages of the standard PCC are the long life of the filter construction and the resistance of filter breakdowns. The filters are available in different material configurations.

Filters matched to production

Due to the ring filter technology used the filter body acts as an extension of the separating vessel. Ranging from simple installation and removal to compliance with hygienic design, this technology offers many advantages. In addition, the filter is completely FDA-compliant. The long life of the filter designs and resistance to filter breakdown are further advantages. Different filter materials are available, allowing a flexible response to the needs of different products. During the conveying process, the product gas mixture is sucked through a hose or pipe system and travels through the product inlet valve into the separating vessel of the conveyor. In the separation vessel, the fine dust particles are deposited on a ring filter. The product gas mixture is now separated again. Due to gravity, the product settles into the container. After the intake cycle is completed the ring filter is cleaned by compressed air, by reversing the gas flow direction. The particles, fixed to the filter, fall into the separating vessel.

By considering the complete system of pneumatic conveyors, we met the high requirements concerning hygiene, safety and gentle handling of product and operator. Hecht Technology uses PCC technologies to meet the highest containment requirements for a closed transport which protects the health of the operators and prevents cross-contamination. The system can deal with the different requirements and applications of the in-house supply of raw materials. In this way, the PCC Conveyor combines the process steps in the pharmaceutical, chemical and food industries intelligently, safely, gently and without segregation.

.jpg)