The developers of the SR stainless steel enclosure series did not have an easy task. They faced the challenge to develop a product range that would be able to cover the entire spectrum of stainless steel-based enclosure solutions for Atex and IECEx applications in the process industry. This meant that all possible customer requirements regarding enclosure sizes, mounting options, operating temperature, and optional accessories, etc. had to be considered.

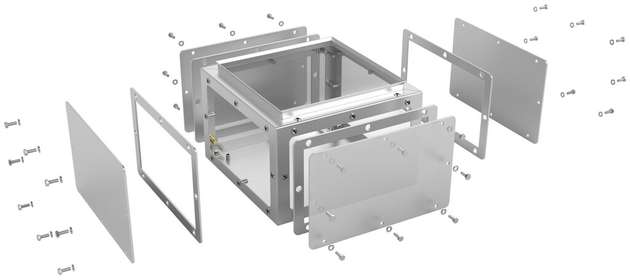

These and many other requirements have been met to an impressive extent by the developers of this series. The brand-new SR enclosure series is more flexible and modular than almost any other on the market. Customers work together with sales specialists to build their specific solution from this modular system. More than thirty enclosure sizes can fulfill almost every requirement for enclosure solutions in process automation. All of the size options have the flexibility to be installed horizontally or vertically, as needed.

Hinges can be mounted for both vertical and horizontal orientation. Of course, this is only if the customer chooses hinges for their solution in the first place. Furthermore, the customer can opt to position cable entries directly in the individual enclosure sides, or they can choose a solution with gland plates, which can be equipped as desired. Each side of the enclosure can be equipped with a gland plate. Customers can also choose how to mount the enclosure solution. The customer can either use the mounting brackets included in the scope of delivery, which can be rotated by 90 degrees, or screw the solution directly to the wall or a designated frame using a rivet nut.

The array of possible solutions is almost limitless. For requirements with access restrictions, Pepperl+Fuchs offers optional cover security hasps or 1/4 turn key locks. The number and orientation of DIN mounting rails can also be selected completely individually. The customer can even choose the material for the earth stud (nickel-plated brass or SS316 stainless steel) and mounting plates (galvanized or stainless steel).

The highest level of explosion protection

However, the modularity and flexibility does not offer added value if the actual customer benefit, namely explosion protection, is not guaranteed. And as expected, Pepperl+Fuchs does not let its customers down here. This is because the SR enclosure series is certified according to the types of protection for increased safety (Ex eb), protection against dust (Ex tb) and intrinsic safety (Ex ia) for use in hazardous areas in Zones 1/21 and 2/22.

Depending on the electrical components installed, the solutions can be used in ambient temperatures from -60 °C to 120 °C. The especially good heat dissipation of the brushed enclosure also enables use in temperature classes (T Class) such as T5 and T6. The enclosure series also meets all requirements of safety class IP66. This is ensured by a foamed silicone seal on the cover, which rests on a return flange that is angled 45 degree when closed. This guarantees permanently safe IP protection, since water can drain off to the right and left of the drainage edge without exerting pressure on the seal. Of course, the enclosures are also impact-resistant up to 7 joules and offer protection against electrostatic charge (surface resistance < 1 GΩ). Highly qualified Pepperl+Fuchs employees make sure the electrical components requested by the customer are installed safely. In consultation with the customer, the solution shall be designed to ensure compliance with the maximum power dissipation and the creepage and clearance distance requirements to prevent the occurrence of sparks.

However, in order to guarantee explosion protection according to the requirements of the IEC/EN 60079-7 standard, the customer must also do their part to ensure safe installation of the system. The customer must make sure conductors with a thermal resistance suitable for the application temperature are selected. A high contact resistance must also be ensured during installation in the plant, such that mechanical stress on the cable cannot cause the conductor connection to become loose.

Range of Solutions for the Process Industry

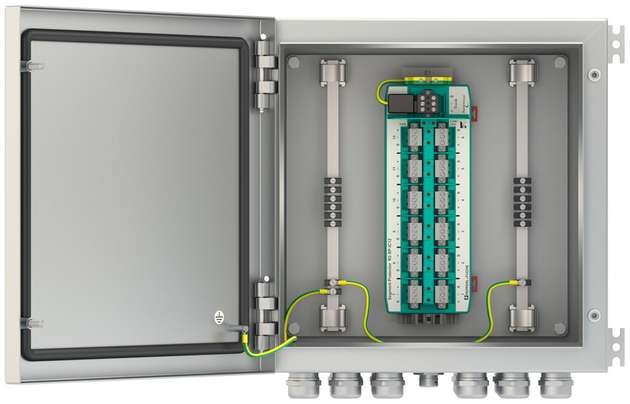

To provide customers with the best possible support in this area, Pepperl+Fuchs serves as a full-service provider for Ex-certified enclosure solutions. In close cooperation with customers, the engineers design customized solutions for on-site use. The SR stainless steel enclosure series is used as the basis for many explosion-protected enclosure solutions. By using electrical components that are also explosion-proof, we can then create customer solutions certified according to the Ex eb, Ex ia or Ex tb types of protection, such as terminal or control stations, switch disconnectors and safety switches, control units, fieldbus distribution panels, and remote I/O field units.

In addition to customer-specific solutions, standardized or partially standardized solutions are also offered. These are especially attractive to customers who are looking for pre-assembled solutions with especially short delivery times. Usually, these are products that often have the same intended purpose, such as junction boxes and control units. However, fieldbus distribution panels and remote I/O field units are also offered as standard versions, which can be ordered either directly with the item number or after a simple configuration with the type code provided. For the latter, for example, predefined enclosure sizes and enclosures equipped with backplane(s) and cable glands are offered, which the customer can then have equipped with up to 64 I/O modules (FB or LB system) for Zone 1 or Zone 2 applications according to their intended purpose.

Ex e control and distribution solutions

All solutions based on the SR enclosure series are combined with the overarching service concept from Pepperl+Fuchs, which is characterized by a high degree of vertical integration and constant close support for the users. In addition to the globally represented regional sales team, product specialists are on hand to implement all project steps in the Solution Engineering Centers (SEC) – also located around the world – from solution design and detailed engineering to approval and on-time, high-quality production of the customized control and distribution solutions.

.jpg)

%20(1).jpg)