Read more in an interview with Alois Billigen, Division Manager for Marketing & Documentation at Azo.

Thousands of pharmaceuticals can be found in the cabinets of German pharmacies – in the form of tablets, capsules or ampoules. In 2016 alone, according to the German Association of the Pharmaceuticals Industry (Bundesverband der Pharmazeutischen Industrie, BPI), medication to the value of EUR 31.4 billion was sold in Germany. For the pharmaceuticals sector, the sheer volume of medication products that this figure represents would be inconceivable without the help of automation.

The pharmaceuticals company Teva acquired Merckle and its subsidiary Ratiopharm in 2010 is just one pharmaceuticals manufacturer among many that uses automation in its production operations. The company has been working closely for many years with Azo, a manufacturer of automation solutions. When building its plant in Blaubeuren near Ulm in Baden-Württemberg, Merckle/Ratiopharm chose Azo to supply it with feeding and control technologies. The aim was to be able to manufacture more than 250 recipes among which the ten most important ingredient materials are fully automated. No problem for Azo! The company, with its head office located in Osterburken in Baden-Württemberg has been engaged for more than 20 years in solutions involving automated guided vehicle systems (AGV) in the automatic handling of raw materials.

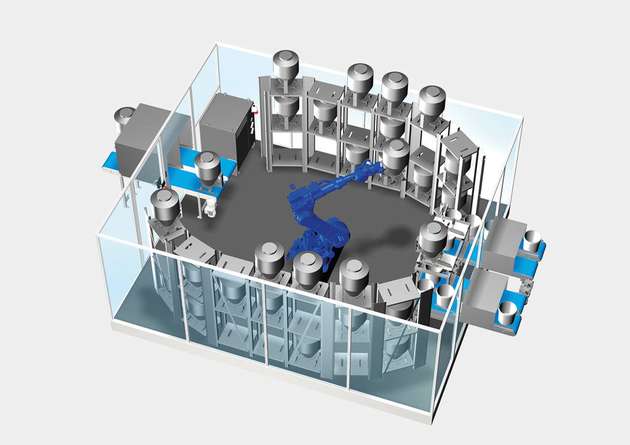

Container system with AGV

Automatic weighing in is performed by the Azo Componenter, a flexible container system with AGV, on two levels. In the upper area, the provisioning level, there are ten containers with an integrated dosing screw (Azo Dositainer). Above each Dositainer is another container. The advantage of this concept: If the upper container is empty, it can be replaced without any problem – during ongoing operations. The Dositainer at Merckle/Ratiopharm works as a dosing device for the Componenter located below it.

The optically controlled AGV drives through below the ten dosing points and collects precisely weighed ingredients for each recipe in a container. With a batch size of 500 kg, precision of ±100 g is achieved. Transponders and infrared interfaces make precise positioning possible, as well as secure data interchange with the process control system. This keeps the route driven free of rails or drag chains. Use of two “park positions”, allows the AGV vehicle to avoid waiting times for transferring a full raw material container or taking on an empty one.

With this system the pharmaceuticals company was able to increase its output performance by a factor of 1.5. A central process control and visualisation system delivers process transparency and production safety. The automatic feeding system also meets the requirements of Merckle/Ratiopharm in relation to safety, cleanliness, hygiene and monitoring/control. For example, the connecting tubes between the two levels can be pulled out using cables. This makes cleaning easier between changes of product.

AGV solutions can be integrated in existing structures. They provide scope for modifying the layout and for changing the sequence of transport operations. It is also no problem to integrate several AGV units. Azo employees use a simulation tool to establish the required number of AGV units: depending on the number of components and the complexity of the pharmaceuticals recipes, the use of several AGV units can provide greater flexibility for the weighing in of medium-sized and small components.

Robots for bagged goods

The automation of medium-sized and small components using container systems in conjunction with AGV is just one example of unmanned raw materials logistics. For the transformation and provision of components in bags, depalletizing robots with automatic bag emptying capabilities are employed. The robots provided by Azo have image recognition capability to enable them to identify and automatically unstack pallets of bagged materials. These bags and sacks are opened and emptied entirely automatically, which is also true of the equipment for pressing empty sacks flat and for tying them up in bales.

The benefits of robot-based depalletizing are self-evident. Flexibility and production output are increased, and workplace conditions are improved. The robot can therefore perform unpleasant and laborious tasks, and human operatives no longer have to handle bags and sacks manually – frequently a monotonous and tiring task. This prevents medical conditions associated with repetitive tasks from occurring. Also, robots can be used flexibly for various sizes of pallet and bag or sack, all of which can be stacked in a multiplicity of different ways. Having said that, it is rare to find depalletizing robots at work in the pharmaceuticals sector where the batch sizes and volumes in production tend to be smaller than comparable recipes and weighing-in quantities in other sectors. The transformation of raw materials in the pharmaceuticals sector frequently involves the use of big bags, while bagged materials are less common. Consequently, in many cases, an investment in robot-controlled depalletizing systems does not make financial sense.

Robots for the micro quantities

However, the dosing of micro quantities of up to 10 kg is a different matter. Previously, this task fell mostly to the operator: every component in a recipe must be weighed out by hand and brought into the production process. This becomes problematic in the case of highly critical materials that may constitute a health hazard. Special protective measures need to be taken here as a precaution. New pharmaceutical products, such as those used in the treatment of cancer, are toxic to machine operators, even in minute quantities. At the same time, contamination of the product – for example by people – needs to be prevented. Manual handling also comes with the inherent risk that it may not be possible to reproduce complex recipes precisely in a consistent manner.

In this context, Azo has developed a robot-based solution for the dosing of micro quantities. The Azo Rolog will be launched onto the market at the end of this year. This robot moves raw materials into and out of storage. A specially developed device handles the dosing, accurate to within one gram, of individual components. The various raw materials, e.g. active ingredients, are provided in dosing and storage units. A safety cell provides a line of demarcation between the working area of the robot and the general production environment, protecting the human operator as well as the product. The Azo Rolog puts each batch together entirely automatically. The dosing and storage units meter out the required micro quantities at the dosing point. The minimum quantity here is 50 g. After weighing in all components, the robot is ready for other tasks, meaning that 24/7 production is possible.

Progress only with automation

These three examples show that, for the transformation of raw materials, the automatic weighing in of medium-sized and small components and of micro components, systems are now already in use across all sectors that work with a high degree of automation – yet are nonetheless flexible, while also assuring a high level of safety in production. The advance of automation within the process industry is now unstoppable.

Here is what this means for the manufacture of pharmaceuticals: the more progress is made by pharmaceuticals research, the more complex the recipes become, and the sale of pharmaceuticals continues to rise. Without robots and AGV solutions, this is not a practically feasible proposition.

SIGMATEK.jpg)